Automation of In-field Job Planning and Performance Optimization

Description

The company wanted to build a solution that would estimate time spent on pre-installation procedures and set job priorities. The goal was to cut overhead expenses, increasing productivity of technicians.

The customer

A global manufacturer of housing / building products has accelerated job planning and is now saving $1,000,000 per year.

The company is involved in a broad spectrum of housing-related businesses: manufacture and sales of building materials and housing equipment, operation of home centers and a network of home-building franchises, real estate services, etc.

The project is a job planner that builds optimal working schedules, setting priorities for the customer’s installation teams. Due to collaboration with Altoros, the customer:

- Automated job planning, reducing time spent on installation / logistics

- Cut overhead expenses, saving around $1,000,000 per year

- Accelerated development cycles by 1.5 times

- Improved performance of the job planning system, speeding up data processing by 2x and search by > 10x.

The need

Prior to engagement with Altoros, the customer’s worker schedules were created manually. The company wanted to build a solution that would estimate time spent on pre-installation procedures and set job priorities. The goal was to cut overhead expenses, increasing productivity of technicians. The company tried to create an automation system internally, but was not satisfied with deliverables. So, LIXIL turned to General Electric for assistance. As a partner of GE, Altoros joined the engineering team to accelerate the development of the planning system and also fix performance bottlenecks.

The challenges

During the project, the developers had to address the following challenges:

- The existing process of building job schedules was overcomplicated—due to default settings and limitations of an OptaPlanner-based data processing module.

- The validation mechanisms for data-entry forms required unification.

- A decent level of security should be ensured, since the system was integrated with a number of IoT / mobile devices.

The solution

To speed up development and delivery, Altoros relied on GE Predix—an Industrial IoT platform based on the Cloud Foundry PaaS. The architects also applied the hexagonal architecture methodology—isolating business logic in different app layers—to get rid of redundant structures. This approach eventually accelerated the development process by 1.5x.

Using Spring Data and Apache OpenJPA, Altoros’s engineers optimized the domain model of the automation system, streamlining requests sent to the database. In addition, the team customized a number of OptaPlanner’s parameters to improve performance of uploading and analyzing data. As a result, the speed of data processing was improved by a factor of two. To optimize search across the database, the team implemented the CQRS (Command and Query Responsibility Segregation) pattern. Now, any type of entities can be found 10+ times faster.

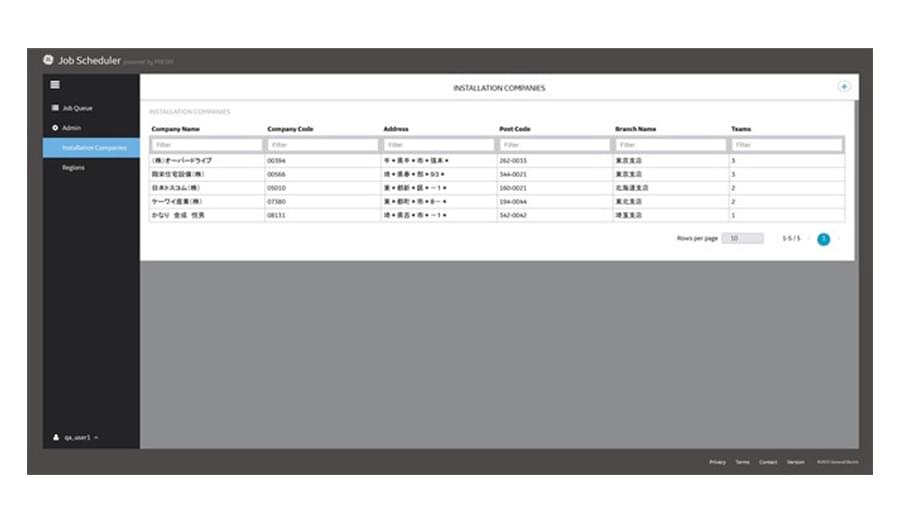

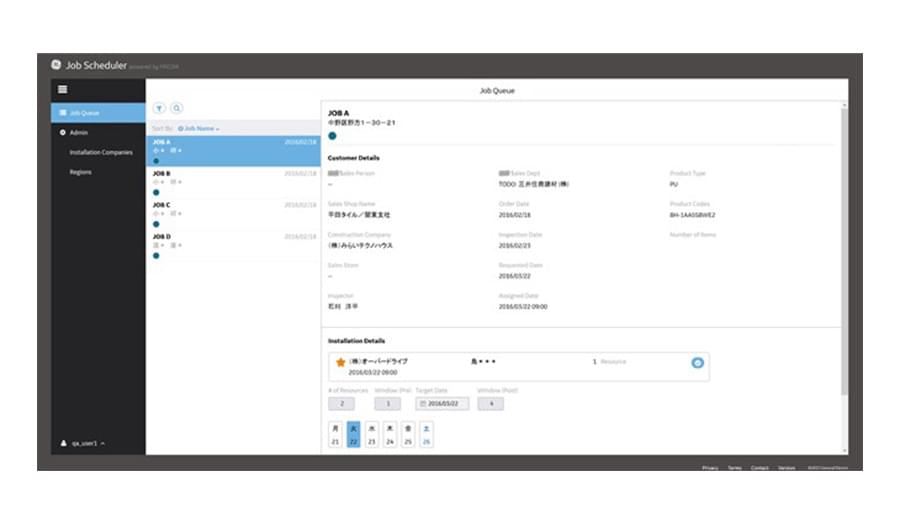

To unify input data, the experts at Altoros created a library that validates any types of forms and supports two-way data binding. The library allows for describing constraints in a declarative way and validating forms of any nested type. It also guaranteed thorough verification of the uploaded data. To ensure security of the system, the team utilized the UAA identity management service of the Predix platform. The OAuth protocol allowed for tuning authentication / authorization processes for third-party devices. Using the Polymer library, our team also visualized job statuses to check the current progress of each scheduled job.

The outcome

As a result of this cooperation, LIXIL has automated job planning for its installation teams. Altoros has also helped the customer to fix performance bottlenecks of the automation system: the speed of data processing was increased by 2x, while data entries can now be found 10x faster. In addition, the customer service has been improved, since pre-installation procedures and logistics now take less time.

The delivered solution has enabled the company to save around $1,000,000 per year. Using the GE Predix IoT platform has helped the customer to save extra $150,000 on cloud infrastructure operations / support.

Technology stack

Server platform

Cloud Foundry, Predix

Programming languages

Java, JavaScript

Technologies

OptaPlanner, AngularJS, Polymer, Spring Data, Spring Boot, Apache OpenJPA, RabbitMQ, Activiti, Rally, CQRS, Node-RED

Databases

PostgreSQL

Client Platform/Application Server

Apache Tomcat

Contact us

Jan-Terje Nordlien

Daglig leder

jan-terje@altoros.no+47 21 92 93 00Altoros Norge AS

Org.nr.: 894 684 992

Tordenskiolds gate 2,

0160 Oslo